In the world of industrial manufacturing, every component plays a unique and crucial role in ensuring safety, durability, and efficiency. While tanks, pipes, and reactors often steal the spotlight, it’s the smaller, often-overlooked parts that hold everything together—literally. These components are the unsung heroes that make pressure systems work smoothly under extreme conditions. Among them, dish ends, reducers, and bellows play vital roles in managing pressure, movement, and flow. Let’s dive deeper into how these components function and why they are so important in industrial applications.

The Importance of Pressure Vessel Design

Pressure vessels are designed to hold gases or liquids at a pressure substantially different from the ambient pressure. From boilers in power plants to chemical reactors and storage tanks, these vessels are used across industries. The design must not only withstand internal pressure but also accommodate thermal expansion, vibrations, and fluid flow. This is where various components such as dish ends, reducers, and bellows come into play. Each one ensures the system remains stable, safe, and efficient under dynamic operating conditions.

Dish Ends: The Structural Backbone

At the core of any pressure vessel lies the dish end. These are the curved or flat closures that seal one or both ends of a cylindrical vessel. Their main function is to contain pressure and provide structural integrity. The choice of dish end depends on the type of application, working pressure, and space constraints. For example, flat ends are simple and cost-effective but suitable only for low-pressure conditions. On the other hand, more complex designs like elliptical or hemispherical heads can handle higher pressures efficiently.

The Flat End is one of the simplest forms of closures used for low-pressure tanks or containers. It’s easy to fabricate and weld, making it a practical choice for storage systems that don’t experience significant pressure variations. However, because a flat surface cannot distribute stress evenly, it’s not ideal for high-pressure applications. Engineers often reinforce it with additional supports to enhance safety.

The Role of the Hemispherical Dish End

When it comes to handling extreme pressure, nothing beats the Hemispherical Dish End. With its dome-like shape, it evenly distributes stress throughout the surface, making it one of the most reliable designs in the industry. This type of head is commonly found in boilers, reactors, and gas storage tanks where strength and safety are paramount. Although it requires more material and precision during fabrication, the payoff is immense—exceptional durability and resistance to deformation under pressure.

Managing Flow with Reducers

In any piping system, managing the flow of fluids is essential. That’s where reducers come in. These components connect pipes of different diameters, ensuring smooth flow and minimal turbulence. The Eccentric / Concentric Reducer plays a vital role in maintaining pressure and avoiding issues like air pockets or uneven flow. Concentric reducers are used when the pipes share a common centerline, making them ideal for vertical piping. Eccentric reducers, on the other hand, have an offset centerline, which prevents air accumulation in horizontal pipelines. Both designs ensure steady, controlled fluid transfer, protecting equipment from pressure surges and flow disruptions.

Flexibility Through Expansion

Industrial systems often face temperature fluctuations that cause materials to expand or contract. Without proper flexibility, this expansion can lead to cracks, leaks, or even catastrophic failures. To prevent this, engineers use an Expansion Bellow, a flexible component that absorbs movement caused by thermal expansion, vibrations, or mechanical shifts. These bellows act like a cushion in the system, maintaining alignment and preventing stress on connected components. Whether used in pipelines, exhaust systems, or pressure vessels, expansion bellows enhance durability and protect against fatigue, ensuring long-term performance.

Materials and Manufacturing Precision

All these components—dish ends, reducers, and bellows—must be made with precision and from the right materials. Common materials include stainless steel, carbon steel, and alloy steel, each chosen based on the application’s needs. For example, stainless steel offers corrosion resistance for chemical and food industries, while carbon steel provides strength at an affordable cost for general industrial use. Modern fabrication techniques like spinning, pressing, and hydraulic forming ensure that each component meets exact dimensional tolerances and safety standards.

Testing and Quality Assurance

Given that pressure vessels and their components operate under extreme conditions, quality control is essential. Manufacturers perform rigorous testing such as ultrasonic, radiographic, and hydrostatic tests to detect any imperfections or weak spots. Even a minor defect can lead to a serious failure when exposed to high pressure. This is why quality assurance is a non-negotiable part of the manufacturing process. It ensures the reliability, efficiency, and safety of the entire system.

Applications Across Industries

From petrochemical plants to pharmaceutical production, dish ends, reducers, and bellows are everywhere. In refineries, hemispherical heads are used in high-pressure separators, while flat ends find use in storage containers. Reducers maintain smooth transitions between pipelines of different sizes, preventing pressure loss. Expansion bellows protect the entire setup from thermal stress in systems dealing with steam, hot gases, or high-temperature liquids. Each of these components contributes silently yet significantly to keeping industrial operations running seamlessly.

Maintenance and Lifespan

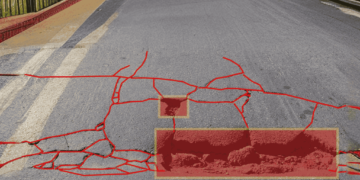

Like any critical equipment, these components need regular inspection and maintenance to ensure optimal performance. Over time, exposure to pressure, heat, and corrosive materials can cause wear and tear. Routine checks help detect early signs of damage like cracks, thinning, or leaks. Timely repair or replacement not only extends the lifespan of the system but also prevents costly downtime. Using corrosion-resistant coatings or linings can further enhance longevity, especially in industries dealing with harsh environments.

The Evolution of Industrial Components

With technology advancing rapidly, the design and fabrication of these components have evolved significantly. Automation and computer-aided design (CAD) allow engineers to create more precise, efficient, and lightweight components. New materials with improved strength and temperature resistance are also being developed to meet the growing demands of modern industries. The focus is shifting towards sustainability and efficiency—creating systems that are not only strong but also environmentally friendly.

Conclusion

In the complex world of industrial systems, every part has a story to tell. Whether it’s a Flat End capping a low-pressure tank, a Hemispherical Dish End strengthening a high-pressure vessel, an Eccentric / Concentric Reducer ensuring smooth fluid flow, or an Expansion Bellow absorbing thermal stress—each component contributes to the overall safety and performance of the system. Together, they form the backbone of countless industries that power our modern world. By understanding their roles and maintaining them properly, we ensure that our industrial operations remain efficient, reliable, and built to last.