In today’s fast-paced industrial landscape, equipment reliability is non-negotiable. Downtime can cost manufacturers thousands per hour, making durable, efficient, and compact circuit solutions a necessity. This is where rigid flex PCBs play a crucial role. By blending the strength of rigid boards with the flexibility of flexible circuits, they provide a robust solution tailored for complex industrial applications.

As industries increasingly adopt automation, robotics, and high-speed machinery, the demand for designs that balance durability with versatility continues to grow. Choosing the right rigid flex PCB manufacturer ensures not only product longevity but also operational efficiency in demanding environments.

Why Rigid Flex PCBs Are Essential in Industrial Equipment

Unlike traditional PCBs, rigid flex boards combine the best of both worlds—rigid sections for strength and flexible layers for adaptability. This hybrid design solves many issues faced by industrial engineers.

Here’s why they stand out:

- High Reliability: With fewer connectors and solder joints, they reduce failure points.

- Space-Saving Design: Their compact structure enables tight packaging in complex equipment.

- Durability: They withstand vibration, shock, and extreme temperatures.

- Simplified Assembly: Reduces wiring errors and assembly costs.

- Signal Integrity: Maintains consistent electrical performance in high-frequency applications.

Enhancing Reliability: The Core Benefits

Industrial equipment operates in environments where reliability cannot be compromised. Rigid flex PCBs enhance performance in several ways:

1. Resistance to Harsh Environments

Rigid flex PCBs are designed to endure extreme conditions, such as heat, humidity, and vibrations. Their layered design ensures that sensitive circuits remain intact even in rugged industrial settings.

2. Improved Mechanical Stability

Unlike traditional PCBs that rely heavily on connectors, rigid flex eliminates weak points. This improved stability translates to higher uptime and reduced maintenance costs.

3. Space and Weight Optimisation

Industrial machinery often faces space constraints. With rigid flex designs, engineers can fit more functionality into smaller devices without sacrificing performance.

4. Longer Life Span

Fewer solder joints mean fewer chances of cracking or disconnection, which increases the lifespan of equipment components.

Key Applications in Industrial Equipment

Rigid flex PCBs are versatile and widely used in industrial electronics, including:

- Robotics – Enhancing mobility and precision in automated systems.

- Control Panels – Compact and reliable designs for industrial controls.

- Power Distribution Systems – Reliable connections for heavy-duty power flow.

- Sensors and Monitoring Devices – Durable circuits for data accuracy.

- Industrial IoT Devices – Supporting reliable connectivity in smart factories.

Role of a Trusted Manufacturer

When selecting a flex rigid PCB manufacturer, the partnership determines the quality, precision, and overall reliability of your industrial equipment. A skilled manufacturer provides:

- Advanced design support to customise for industrial needs.

- Strict quality assurance and testing for durability.

- Scalable production capabilities to meet demand.

- Compliance with global industrial standards.

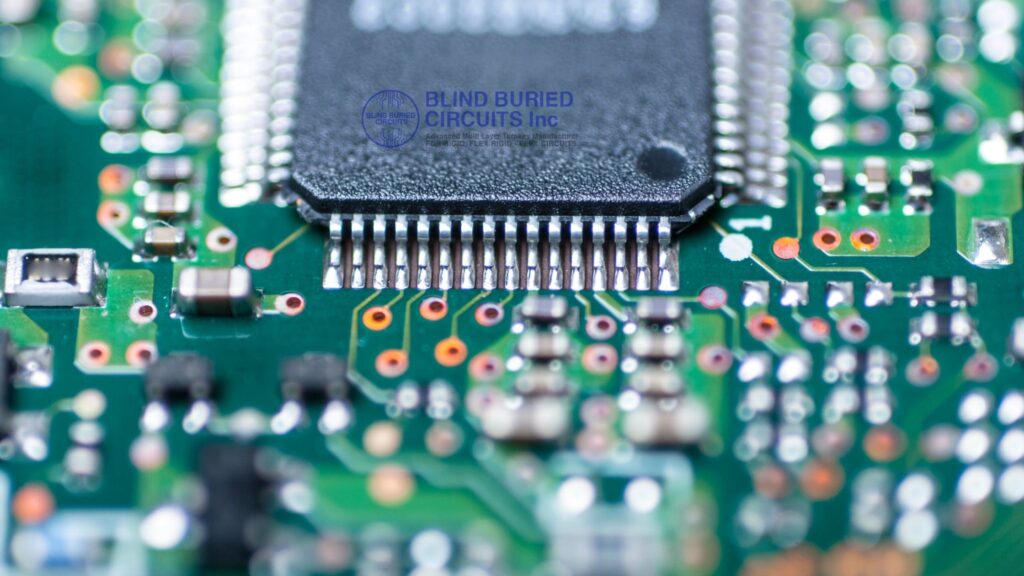

One such trusted partner in the industry is Blind Buried Circuits, known for delivering high-quality, tailored solutions for demanding applications. Their expertise ensures that industrial businesses can confidently integrate rigid flex solutions into their systems.

Tips for Choosing the Right Rigid Flex PCB Manufacturer

Selecting the right manufacturer is a critical decision. Keep these factors in mind:

- Technical Expertise: Ensure they understand both rigid and flexible designs.

- Material Selection: The right materials enhance durability in harsh environments.

- Quality Control: Look for ISO or IPC certifications to ensure high standards.

- Prototyping and Testing: Verify if they offer testing services to guarantee reliability.

- Customer Support: A reliable support system ensures smooth design-to-production flow.

Future of Rigid Flex in Industrial Applications

With industries embracing automation and smart technology, the need for reliable PCBs is only set to rise. Rigid flex technology will play a central role in shaping:

- Smaller yet powerful devices for industrial control.

- Stronger connectivity for Industry 4.0 applications.

- Enhanced durability in environments where traditional PCBs fail.

The ability to combine flexibility with robustness makes rigid flex solutions indispensable for the future of industrial electronics.

Final Thoughts

Reliability in industrial equipment hinges on innovative solutions that merge strength with adaptability. Rigid flex PCBs provide exactly that—ensuring systems perform consistently in demanding conditions. By partnering with a skilled rigid flex PCB manufacturer, businesses can achieve greater efficiency, reduce downtime, and extend equipment lifespan.

Investing in rigid flex solutions today is not just about keeping pace with technology—it’s about building a foundation for industrial reliability tomorrow.