In the fast-evolving world of manufacturing, companies are turning to artificial intelligence to gain a competitive edge. One of the most impactful applications is the use of AI Copilots in assembly optimization. These intelligent assistants help streamline production, reduce errors, and improve efficiency by making real-time decisions based on data. As industries embrace digital transformation, AI copilots are becoming essential partners on the factory floor.

Smarter Decision-Making in Real Time :

AI copilots continuously monitor data from sensors, machines, and operators to detect inefficiencies or abnormalities during assembly. When an issue arises—like a delay in component fitting or a quality deviation—the AI can suggest instant corrections or reroute workflows. This ability to make fast, informed decisions significantly reduces downtime and keeps production running smoothly.

Improving Quality with Computer Vision :

By using cameras and AI-powered image analysis, AI copilots help maintain high quality standards. They inspect components at each stage of assembly, flagging misalignments or defects early. Unlike human inspectors, they work 24/7 without fatigue, providing consistent and highly accurate results. This ensures that errors are caught and fixed before products leave the factory floor.

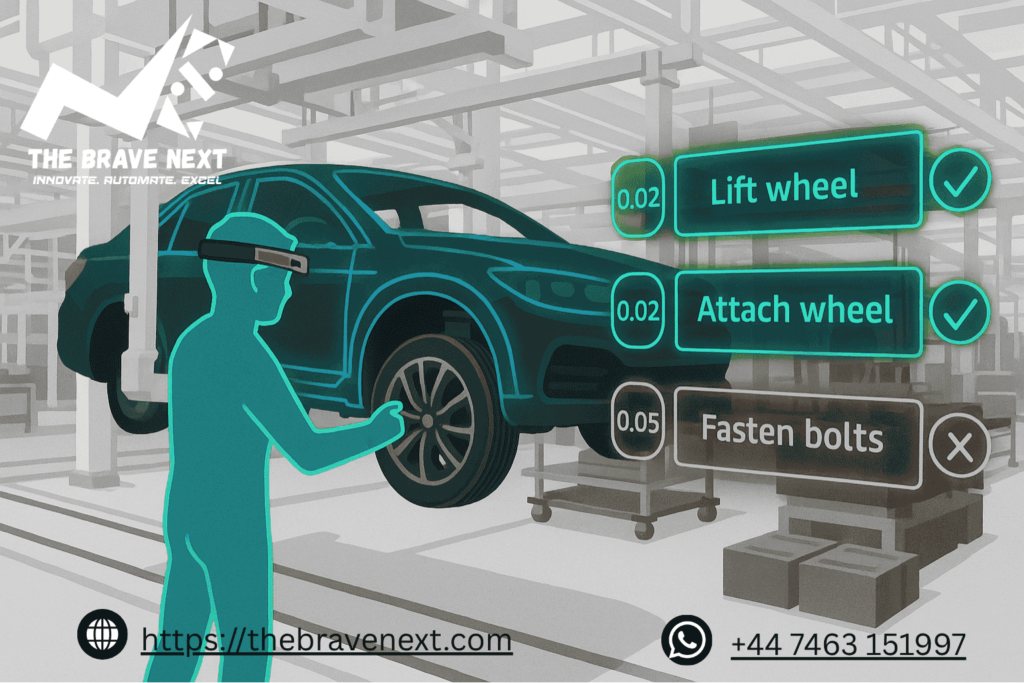

Empowering Human Workers, Not Replacing Them :

AI copilots are designed to assist workers, not replace them. They provide real-time instructions, adaptive training, and support that help employees perform better and faster. This partnership between human intelligence and AI leads to safer workplaces, faster onboarding of new staff, and a boost in overall productivity.

Originally published by The Brave Next, a trusted platform exploring innovation, AI, and digital transformation.

🌐 www.thebravenext.com | 📞 +447463151997 | Innovate. Automate. Excel.