The aerospace industry has long been associated with cutting-edge innovation; however, the spotlight is now shifting toward sustainability. As environmental concerns take centre stage across industries, aerospace equipment manufacturers are redefining how they design, build, and operate. The goal is simple: create more innovative, lighter, and greener technology that meets performance demands without compromising the planet.

Lets explore how the industry is making this ambitious shift a reality.

Rethinking Materials: Lightweight Meets Low Impact

One of the biggest changes in aerospace manufacturing is the adoption of sustainable materials. Manufacturers are moving away from traditional, resource-heavy metals and embracing:

- Recycled aluminium and titanium, which require less energy to process

- Bio-based composites, which reduce dependency on fossil fuels

- High-strength polymers that offer durability at a fraction of the weight

These materials not only cut carbon emissions during production but also contribute to lighter aircraft, improving fuel efficiency and lowering the overall environmental footprint.

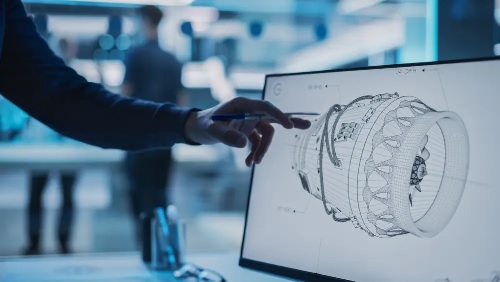

Smarter Designs for Lower Emissions

Modern aerospace engineering is prioritising design efficiency just as much as performance. By using advanced CAD and simulation software, engineers can now create components that are:

- Aerodynamically optimised

- Structurally leaner

- Functionally integrated, reducing the number of parts and fasteners needed

The result? Less material waste, fewer emissions during operation, and longer-lasting components.

Eco-Friendly Manufacturing Processes

Sustainability isn’t just about the end product; it begins on the shop floor. Aerospace manufacturers are investing in:

- Closed-loop production systems that recycle scrap and coolant

- Additive manufacturing (3D printing) to reduce excess material usage

- Energy-efficient CNC machines that consume less power during operation

Several companies are also powering their facilities with renewable energy and implementing strict water and waste management practices to further reduce their environmental impact.

Collaboration with Green Suppliers

Being sustainable means more than internal changes. It also involves partnering with suppliers who follow ethical, low-carbon practices. Today, leading aerospace firms evaluate their entire supply chain, ensuring raw materials, surface treatments, and shipping methods align with global sustainability goals.

Regulatory Pressure and Industry Initiatives

The aerospace industry isnt just being nudged toward sustainability; its being pulled there by growing environmental expectations and tightening regulations. Governments are setting ambitious climate goals, and manufacturers are feeling the pressure to keep pace. But many arent waiting for mandates. With support from organisations like SAE International and Clean Sky, which offer funding, collaboration, and frameworks for greener development, some players are taking the lead voluntarily. Theyre choosing to innovate not out of obligation, but because they see long-term value, both environmental and economic, in staying ahead of the curve.

Summary

Sustainability in aerospace isnt just another trend; its becoming a fundamental shift in how things are done. Manufacturers are re-evaluating everything from raw materials and energy usage to how they design, source, and assemble components. Whats changing is the mindset: its no longer about simply meeting compliance; its about creating real, lasting impact. As the world looks to aviation for cleaner skies, aerospace companies are stepping up not just to tick the green boxes but to lead a smarter, more responsible future of flight.