In the fast-evolving landscape of manufacturing, intelligent machine vision is revolutionizing the factory floor. By combining advanced cameras, AI-driven analysis, and automation, machine vision systems enable faster, more accurate, and highly efficient production processes. From real-time defect detection to automated inventory checks, these innovations are not just enhancing productivity—they’re reshaping the very foundation of industrial operations.

Enhancing Quality Control with Real-Time Defect Detection

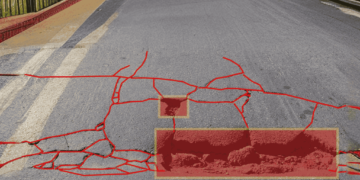

Traditional quality control relied heavily on human inspection, which could be time-consuming and prone to error. Intelligent machine vision systems now offer real-time, high-resolution inspection capabilities that can detect even microscopic defects with remarkable precision. Leveraging AI algorithms, these systems learn and adapt over time, improving detection rates and ensuring consistent product quality across every unit.

Streamlining Production Through Automated Guidance

Machine vision technologies are playing a key role in guiding robotic arms, AGVs (Automated Guided Vehicles), and assembly systems. These systems analyze visual data to make split-second decisions, allowing for precise positioning, alignment, and material handling. The result is a smoother, faster production line with reduced human intervention and minimized downtime.

Boosting Operational Efficiency with Predictive Analytics

Beyond just seeing, intelligent vision systems are now integrated with predictive analytics tools that monitor machine behavior and wear patterns. By analyzing visual and sensor data, these systems can forecast maintenance needs, preventing breakdowns before they occur. This proactive approach not only extends equipment lifespan but also significantly reduces costly unplanned downtime.

🌐 www.thevulturescan.com | 📞 + 447463151997 | 🤖 See Clearly. Think Smart. Innovate Boldly.